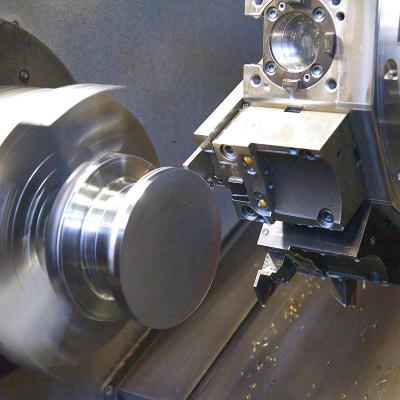

Secondary turning

02/4 axis CNC secondary machining processes for small and medium-sized standard production lots.

Max. diameter:

TURNING Ø MAX 650 X 2000 MM

|

MODEL

|

CHARACTERISTICS

|

CNC CONTROL SYSTEM

|

∅ TURNABLE PIECES - WORKING RANGE

|

|

Mori Seiki ZL 35

|

Powerful machines with high metal

removal rate for 2/4 axis horizontal turning operations with motorised turrets |

Fanuc MSD 501

|

∅ 620 x 1500 mm (lathe steady)

|

|

Mori Seiki SL 403

|

Fanuc MSX 500 II | ∅ 650 x 2000 mm bar passage ∅ 117 mm |

|

|

Mori Seiki ZL 250

|

Machines for 2/4 axis horizontal turning operations with motorised turrets |

Fanuc MSD 501 II | ∅ 400 (T1) ∅ 260 (T2) |

|

Mori Seiki SL 35

|

Fanuc MSC 516 | ∅ 420 mm | |

|

Mori Seiki SL 25

|

Fanuc MF T4 | ∅ 350 x 500 mm | |

|

Mori Seiki ZL 25

|

Fanuc 15 TT | ∅ 400 (T1) ∅ 250 (T2) bar feeder ∅ 71 mm max |

|

|

Mori Seiki NL 3000 MC

|

Mitsubi MSX 850 III | ∅ 450 x 1200 mm | |

|

Doosan Puma 4100 MC

|

Fanuc Oi-F | ∅ 350 x 1100 mm bar passage ∅ 60 mm |

|

|

Mori Seiki NL 3000

|

Mitsubi MSX 850 III | ∅ 450 x 1200 mm | |

|

Okuma Multus B400

|

Lathes & Turning 5 axis multitasking machines with collision avoidance system, hydraulic tailstock and teady rest | Okuma OSP-P200L | Ø 710 mm 230 x 1500 mm |

|

Okuma LU35 MX1500

|

Horizontal lathe 5 axis with servo driven turret | Okuma OSP-P200L | Ø 300 x 1500 mm |